HEAT RECOVERY 7.5 – 132 KW (INTEGRIERT ODER EXTERNE BOX)

-

Category

AIR COMPRESSORS/ SCREW COMPRESSORS

-

Manufacture

RENNER KOMPRESSOREN

Heat recovery for screw compressors

The operation of screw compressors generates a large amount of heat that can be used cost-effectively. Up to 94% of the electrical energy used for generating compressed air can be recovered as heat through consequent implementation of a heat recovery concept. The heat recovery leads to considerable energy cost savings and is environment friendly.

One way of recovering heat is to use the heat radiated by the compressor for heating in the form of warm air via exhaust air ducts.

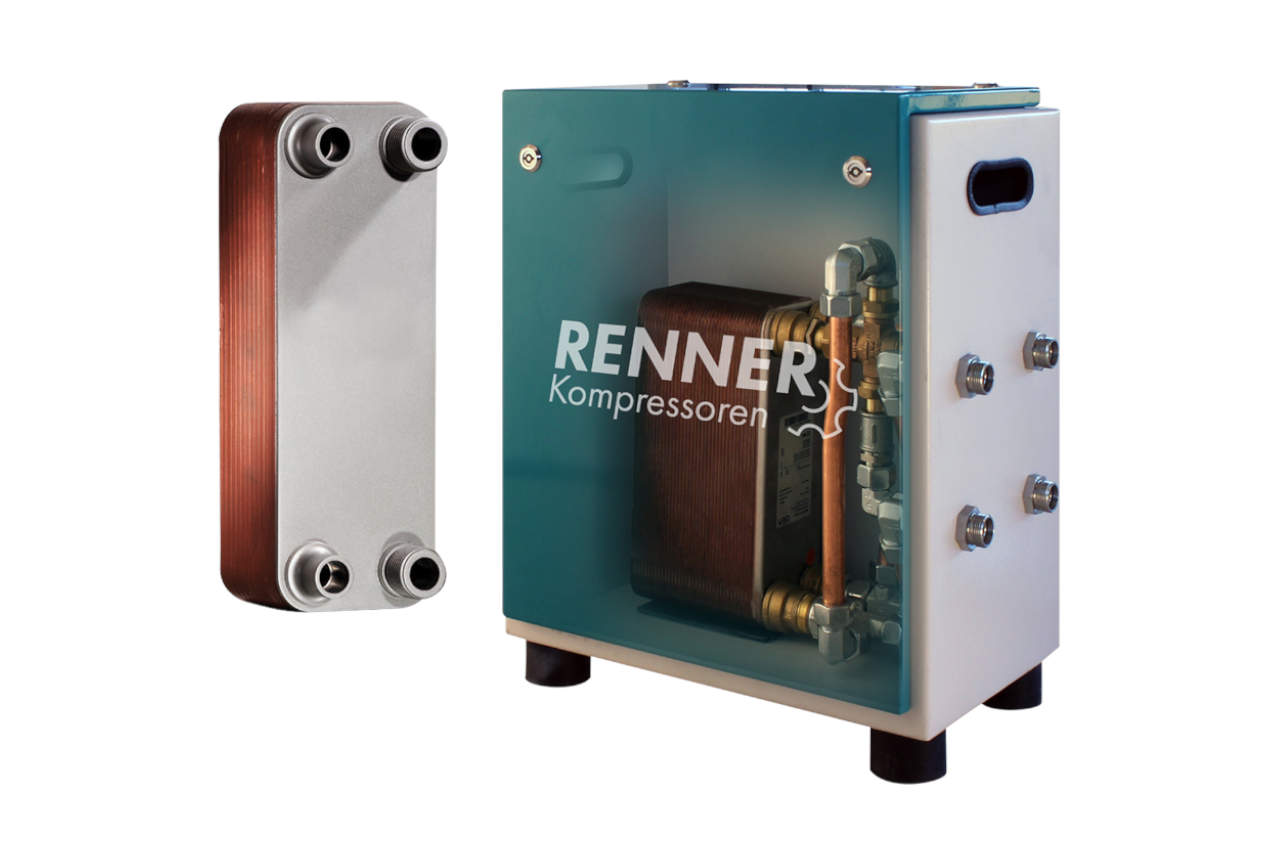

Heat recovery with an oil/water heat exchanger, on the other hand, to heats the process water or heating water up to a temperature of 65°C. The heat is recovered by means of an oil/water heat exchanger. For this purpose, RENNER offers two systems that can also be retrofitted into existing systems and networks:

The integrated plate heat exchanger is installed in the screw compressor and directly integrated into the oil circuit, thus no additional installation space is required. Due to the additionally available water connections, it can be quickly and easily integrated into the in-house water network.

This solution is available for the following compressors:

RS-PRO 2.0-11.0 – 18.5

RS-PRO 2.0-30.0 – 55.0

RS 18.5 – 1-30.0

RS 55.0 – 250

The external heat recovery stand-alone unit is installed in a separate housing. Thanks to its compact dimensions and pre-installed connections, it requires little space and can be integrated into the existing system quickly and easily. External energy is not required for operation.

The stand-alone unit is suitable for the following compressors:

RS-PRO 7.5 – 18.5

RS 18.5 – 1-30.0

RS-PRO 2.0-30.0 – 55.0

RS 55.0 – 132

Double-walled safety heat exchangers are also available for sensitive areas and on request for both systems. Other temperature ranges are available on request.

Advantages

- Considerable cost savings due to the free-of-charge use of the heat energy generated

- Short payback periods thanks to energy cost savings

- Low space requirement due to compact design or integration in equipment

- Easy installation thanks to ready-to-connect components

- Protects the environment, as the energy generated is recycled and used rationally